Timeliness and relevance of scientific problems addressed by the project

Ceramic pigments are inorganic materials containing chromophore transition elements that are added to produce the corresponding colour of the ceramic produced. The pigments form a heterogeneous mixture with the bulk in which they are dispersed, affecting the properties of the ceramic. In addition to colouring properties, ceramic pigments must be resistant to atmospheric and chemical influences, to high temperatures, to the action of silicate melts, and to prolonged exposure to light. Ceramic pigments must be insoluble in water, in organic solvents and binders, but dispersed therein, altering the optical characteristics of the materials. Therefore, the most important optical properties of pigments are the selective absorption and scattering of light of a given wavelength. The requirements for modern ceramic pigments necessitate the search for new mineral matrices suitable for incorporation of chromophore impurities in order to produce new pigments which, at lower concentrations, achieve the same or better optical characteristics. In this regard, and also as a result of new manufacturing technologies developed in recent years, interest in ceramic pigments has resumed, as indicated by the significant increase in publications in this field.

The significance of the proposed project is determined by the fact that the research will focus on the synthesis of new ceramic matrices – analogues of pyroxenes minerals from the solid solution series diopside-hedenbergite and diopside-enstatite. From the other side, the effect of various transition impurity elements on the phase composition, structural and optical characteristics will be studied in order to elucidate the conditions of synthesis, the mechanisms of isomorphic substitution, the change of structural and physical properties, colour and improved functionality.

A relatively recent trend is the development of new ceramic and glass-ceramic materials from waste materials. Therefore, another topical and significant task of the project is to explore the possibilities of utilization of waste products as petroleum refining catalysts and spent vanadium catalyst used for the production of sulfuric acid by developing a technological scheme for the production of harmless and sustainable ceramics. The development of the technological scheme for utilization ofwaste product in ceramic materials will be based on the extensive experience of the working team in this field.

Tests of the applicability of new pigments obtained, which are not part of this project, are envisaged at the ceramic tile factory “Han Asparuh”, Isperih. The proposed project is an original innovative scientific fundamental study, the results of which, however, would subsequently have a serious practical application.

Current state of the research on the problem area

Much of the inorganic compounds, developed as materials, belong to different groups of natural minerals, which are explored from the mineralogical point of view to clarify the geological and geochemical processes of rock formation. The project team from IMC-BAS has considerable experience in studying natural minerals and in particular pyroxenes, which are rock-forming minerals in mafic and metasomatic rocks. Isomorphic substitution leads to a change in the physical properties of the minerals, which is a desired effect used to optimize certain properties of synthetic materials of similar composition and/or structure, developed for various applications. The production of pigments of a certain colour depends on a number of factors such as the type of matrix – the mineral phase, the temperature (most pigments are stable to a certain temperature), the nature of the gas environment during firing, the concentration of the chromophores, the ratio of the basic phases, etc.

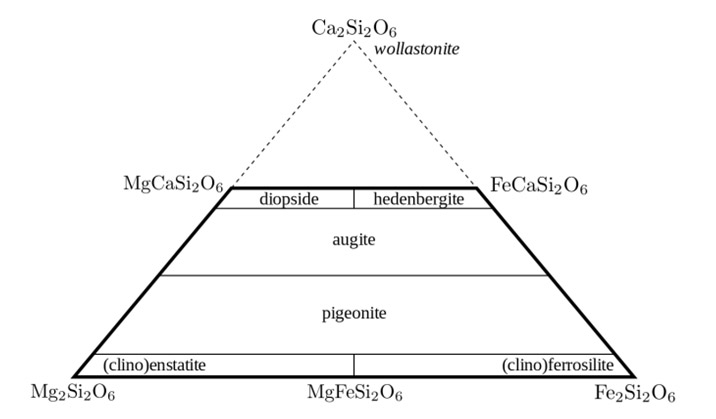

The choice of a pyroxene matrix for the purposes of this project is determined by the crystal-chemical characteristics of the minerals of the pyroxene group, which form a series of solid solutions with complete or limited isomorphic substitution. The structure of pyroxenes consists of single chains linked SiO4 tetrahedra and cations occupying two different crystallographic positions: (M1) octahedral coordinated by 6 oxygen atoms and (M2) six to 8 coordinated. Pyroxenes are divided into two subgroups: orthopyroxenes (OPx-orthorhombic) and clinopyroxenes (CPx-monoclinic) of the general chemical formula ABSi2O6, where A = M2 and B = M1. From a chemical point of view, the pyroxenes are divided into magnesium with divalent Ca, Mg, Fe in cationic positions and sodium pyroxenes with monovalent sodium in M2, whereby the need for charge compensation determines the inclusion of a trivalent ion in M1 position. There is complete mixing in the series of diopside (CaMgSi2O6) – hedenbergite (CaFeSi2O6) solid solution. Since calcium cannot occupy the M1 position, pyroxenes with more than 50 mol% calcium cannot form. Augite (Ca, Na) (Mg, Fe, Al, Ti) (Si, Al)2O6 contains the end members of a series of diopside-hedenbergite, but may also include Na, Ti, Al and other elements in different crystallographic positions. The calcium content of the augite is limited by the differences in compatibility with pigeonite and orthopyroxene.

Figure 1. Composition ranges of the Ca-Mg-Fe clinopyroxenes with accepted names

The choice of a pyroxene matrix for the purposes of this project is also determined by the advantage that the synthesis of diopside can be carried out at relatively low temperatures without using mineralizers. The temperature for the synthesis of ceramics is selected depending on the composition of the mixture in the range 1100-1250 °C. The additional inclusion of impurities can lower this temperature and displace the fields of phase stability. The starting materials for synthesis are mainly oxides – CaO, MgO and SiO2. Despite the appropriate crystalline structure, high temperature resistance and relatively easy synthesis methods, pyroxenes have not been implemented as industrial ceramic pigments. There is a relatively limited number of studies on the synthesis of diopside-based ceramics for glazes and pigment production . Ceramic pigments can be expected in the CaO-MgO-SiO2- (RO or R2O3) system, where RO is CoO, NiO, MnO; R2O3 – Fe2O3, Cr2O3, V2O3, where calcium and magnesium can be partially replaced by chromophore elements.

Recently, cobalt-containing diopside have been most extensively developed, where divalent cobalt can completely replace magnesium in the M1 octahedral position causing absorption in the green (about 500 nm) and the yellow range of the visible spectrum. When Mg2+ is replaced by Co2+, the colour of the pigment changes to pink and purple. When aluminum is added and the partial replacement of SiO2 with Al2O3 occurs, the colour of the pigments is dark blue. The brightest blue color was obtained from Pishch in the CaO.0,1MgO. 0,9СоО 0,5SiO2.1,5Аl2О3 system. The substitution with Al2O3 in this system significantly reduces the synthesis temperature. The introduction of NiO into the starting composition produces dark green pigments. When MgO is replaced with MnO, the colour of the diopside ceramics changes from gray-pink to brown. A similar effect can be expected with the introduction of Fe2O3 instead of MgO. With the introduction of Cr2O3 instead of MgO, the pigment color is expected to change from gray-blue to dark green. In addition to the effects on light absorption and scattering, the role of chromophore elements on crystallization and the reduction of the amorphous phase, as is the case with glass ceramics, will be investigated.

Intensive work has been done recently on the synthesis, characterization and properties of ceramic pigments obtained from various wastes: catalysts from oil industry, spent vanadium catalyst used for the production of sulfuric acid, rice husks, etc.

Pyroxenes, on the other hand, have recently been classified as a new class of multiferroics and are promising in terms of discovering new functionality for these ceramics.

In this aspect, the present project proposal is very relevant because it is an attempt to implement a systematic approach for synthesis and analysis of results obtained with a large set of doping elements in a diopside-augite matrix.

Focus of proposed research in line with the objectives of the National Research Strategy and with societal challenges outlined in it, as well as with regional and European priorities

The proposed project is in line with the objectives of the National strategy for development of scientific research in the Republic of Bulgaria 2017 – 2030, with the objectives of Innovation strategy for smart specialization of the Republic of Bulgaria 2014-2020 (IS3), as well as with the European Research Area priorities.

The implementation of this project will help to overcome to some extent the existing imbalance identified in the Strategy, namely concentration of the funds and infrastructure in Sofia universities and scientific organizations and less in the provincial ones. The Strategy strongly emphasizes that the lack of funds and their irregular provision leads to a decrease in the quality of research, the qualification of scientists, and hence the education and training of students and PhD students.

The cooperation between the two scientific institutions (University of Ruse and IMC-BAS Sofia) for the realization of the common tasks and use of the scientific infrastructure is in accordance with one of the goals of the Strategy – overcoming the imbalance in the territorial distribution of research and infrastructure.

The implementation of this project will contribute to the development of interdisciplinary research and a thorough interpretation of the results, to intensify the links between science and education, and business.

The project will contribute to improving the qualification of the scientific staff, and especially to developing students` skills, personal and professional development of PhD students, postdoctoral students and young scientists in the team.

It is known that the National Research Strategy 2017-2030 explicitly states that targeted basic research will be supported, which can contribute to the development of applied research and business relations. The proposed project is an original innovative scientific fundamental study, the results of which, however, would subsequently have a serious practical application.

According to the goals of Innovation strategy for smart specialization of the Republic of Bulgaria 2014-2020 (IS3, the project is related to technological modernization using resource-efficient /waste-free/, pollution-reducing technologies. When satisfactory results of the project objectives are achieved, an alternative will be given for the recovery of two large industrial wastes – waste catalysts (from Lukoil, Burgas) and spent vanadium waste from the production of sulfuric acid (Aurubis, Bulgaria). The proposed project will contribute to the solution of these problems through the use of residual raw materials.

In line with the European priorities for improving cross-border cooperation for an adequate solution to regional problems, this project proposal includes cooperation with scientists from the Ukrainian State University of Chemical Technology in Dnepropetrovsk, with whom the University of Ruse maintains close contacts and has a long-term cooperation agreement, and with scientists from the Institute of Inorganic Chemistry at the Czech Academy of Sciences, with whom the IMC-BAS group has long-term cooperation.